Solving the Common Problem of Settleability

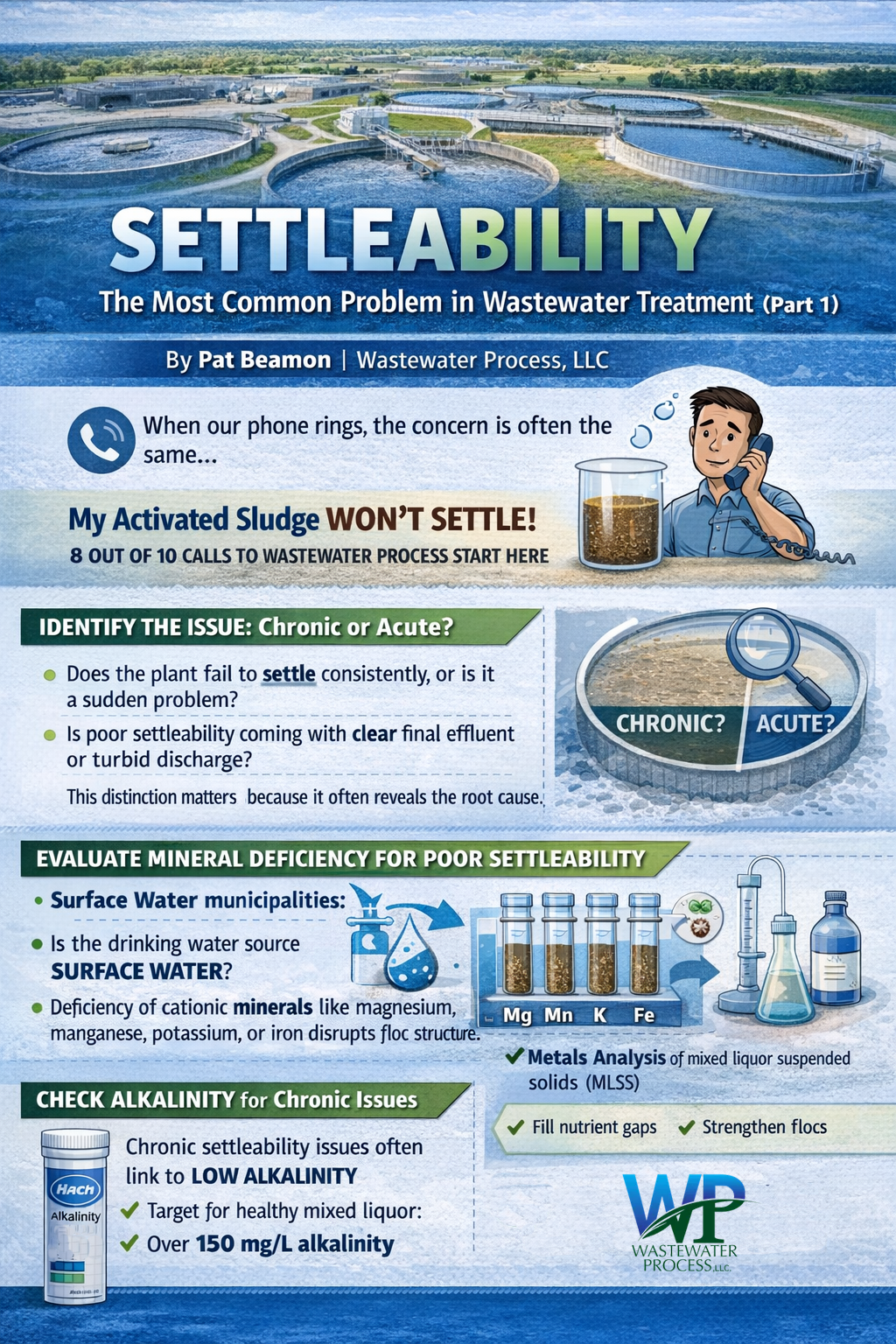

Roughly eight out of ten times the phone rings at Wastewater Process, the conversation begins the same way: “Our sludge doesn’t settle.” Over more than forty years in the wastewater industry, I have taken hundreds of these calls.

The first thing I need to determine is whether the settleability issue is chronic or acute. That distinction matters. I have seen plants with very poor settling characteristics that still produce an excellent final effluent. I have also seen plants with fast, clean settling sludge that discharge a highly turbid effluent. Settleability alone does not tell the whole story, but it is often the symptom that brings deeper issues to the surface.

If you are a municipal facility dealing with poor settleability, one of the first questions to ask is where your city gets its potable water. If your drinking water source is surface water, your wastewater may be deficient in critical minerals. A lack of cationic minerals such as magnesium, manganese, potassium, or iron can directly contribute to poor sludge settleability.

To evaluate this, we like to start with a metals analysis of the MLSS, or mixed liquor suspended solids. This test helps determine whether the biomass is lacking essential micronutrients. When deficiencies are identified, we can recommend targeted nutrient additions to fill those gaps. In most cases, cationic micronutrients are relatively inexpensive and easy to apply. Facilities interested in this approach should contact us for guidance on which micronutrients to test for and what instructions to provide to the laboratory when ordering analyses.

When a plant is experiencing chronic settleability problems, the next critical parameter to evaluate is alkalinity. A healthy mixed liquor should maintain alkalinity above 150 mg/L as calcium carbonate. Without sufficient alkalinity, long-term stability is impossible. Alkalinity acts as the foundation that supports pH. When alkalinity drops to zero, biological activity follows. Zero alkalinity means zero bugs.

Alkalinity can be screened initially using Hach alkalinity test strips. These strips provide a quick snapshot and are useful as a starting point. However, if alkalinity appears low, more accurate testing methods should be used. Titration or spectrophotometric methods provide better precision and are essential when chemical adjustments are being considered. Accurate data ensures that nutrient additions are effective and prevents overcorrection or unnecessary chemical expense.

We will explore these topics in greater depth in future articles. For now, it is important to remember that good process laboratory data is not optional. It is foundational to efficient plant operation, stable treatment performance, and solving settleability problems at their root rather than chasing symptoms.